1、 The production process of injection molding encapsulation: two-step automated molding

The production of liquid silicone injection molded connectors is a highly automated "two-step" integrated molding process, with the core being the integration of solid connector metal terminals/plastic bases and liquid silicone into an inseparable whole in the mold.

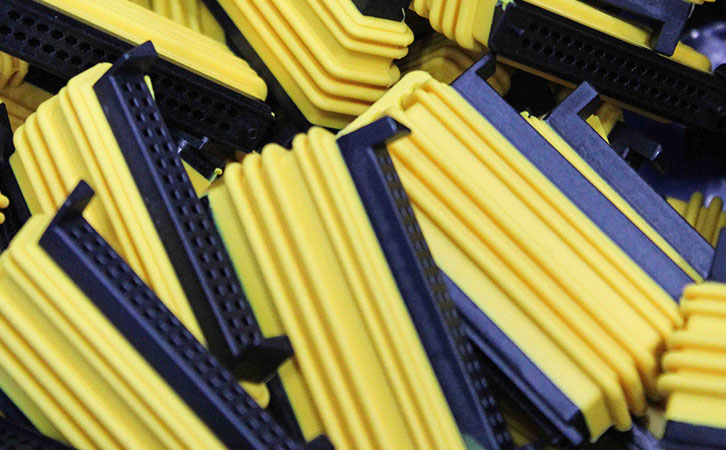

Preliminary preparation and placement of inserts: Firstly, the core electrical connection part (i.e. "insert") of the connector is made by injection molding or stamping, such as PIN pins, terminals, or PBT/nylon plastic bases. These inserts are precisely placed into the designated cavity of a specialized mold using a robotic arm or manual labor.

Measurement and injection of LSR: The liquid silicone raw material consists of two components (A and B agents) and is stored at low temperatures. During production, the metering pump is used to extract and mix in a 1:1 ratio, and a dynamic mixer is used to ensure complete homogenization. The mixed LSR is injected into a preheated (usually 120-180 ° C) mold.

Synchronous molding and chemical cross-linking: Under a certain injection pressure, LSR quickly fills the mold cavity and completely wraps around the predetermined part of the insert. Under the high temperature of the mold, LSR undergoes irreversible thermal vulcanization reaction, rapidly solidifying from liquid to highly elastic silicone rubber body. This process forms a strong physical wrapping and chemical bonding with the insert.

Mold opening and post-processing: After vulcanization is completed (usually within a few seconds), the mold is opened and the finished product is taken out. Due to its good demolding ability, LSR requires almost no trimming. The finished product is an integrated connector with a sturdy structure and complete sealing.

2、 Irreplaceable core function: from connector to sealing system

This process fundamentally improves the performance ceiling of traditional connectors, evolving them from a simple "electrical connector" to a "system level solution that integrates connection, sealing, and protection". Its core role is reflected in:

In environmental sealing: forming a seamless sealing barrier, providing the highest level of waterproof (up to IPX8/IPX9K), dustproof, and moisture-proof performance, preventing internal electronic contacts from being corroded.

Reliable mechanical protection and stress relief: The elasticity of silicone gel can absorb vibrations, reduce impacts, protect fragile solder joints and terminals, and compensate for thermal expansion and contraction differences between materials to prevent cracking.

Electrical and safety performance: Silicone itself is an excellent insulation material that can effectively prevent short circuits and leakage, and has arc resistance and flame retardancy (up to UL94 V-0 level) to ensure electrical safety.

Stable wide temperature range performance: LSR can maintain elasticity and sealing performance for a long time in the temperature range of -50 ℃ to 200 ℃, without embrittlement or deformation.

3、 Wide applicability: a trusted choice for harsh environments

Based on the above advantages, LSR encapsulated connectors have become a standard configuration in many demanding application fields:

Automotive Electronics: New Energy Vehicles (Battery Pack BMS Connector, In Vehicle Charging Port PDU)、 Sensors (oxygen sensors, pressure sensors), ECU control units, LED headlights, etc. are required to withstand high temperatures, vibrations, and water immersion environments in the engine compartment.

Consumer electronics: smartphones (charging ports), wearable devices (smartwatches, heart rate sensors), drones, outdoor Bluetooth speakers, etc., meet daily waterproof and sweat proof needs.

Industry and Energy: Industrial sensors, outdoor communication base stations, photovoltaic inverter connectors, underwater equipment, etc., used in harsh outdoor environments such as high humidity, salt spray, and ultraviolet radiation.

Welcome to Yingtai factory for processing and producing liquid silicone accessories, plastic parts, silicone waterproof seals, injection molded parts, etc.