The production process of liquid silica gel products in Yingtai Factory is as follows:

1. Material preparation: liquid silica gel: select a suitable model (such as lsr). Curing agent: mixed in proportion. Color paste: used for coloring (optional).

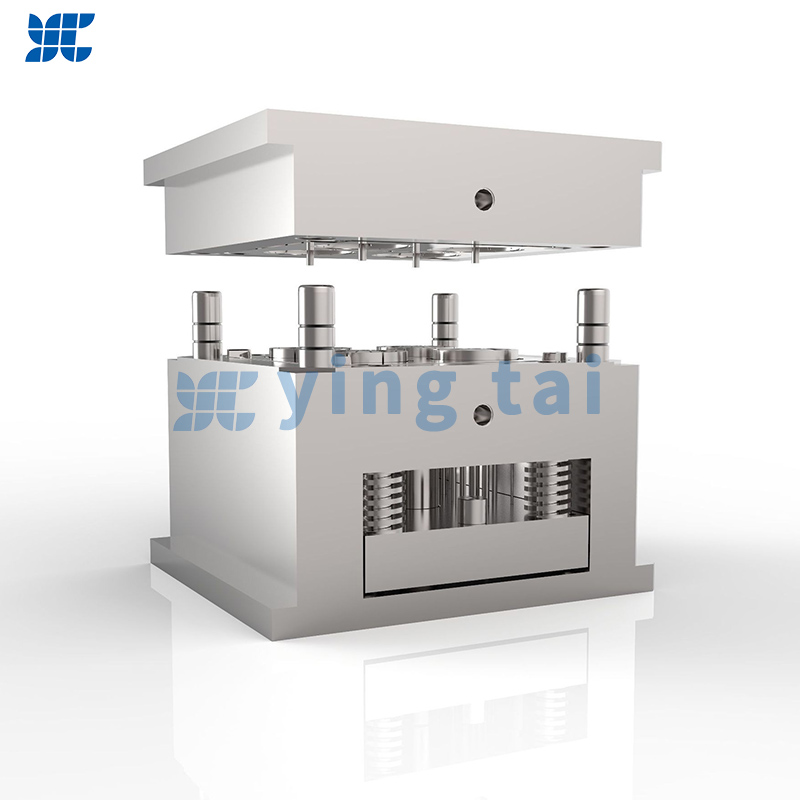

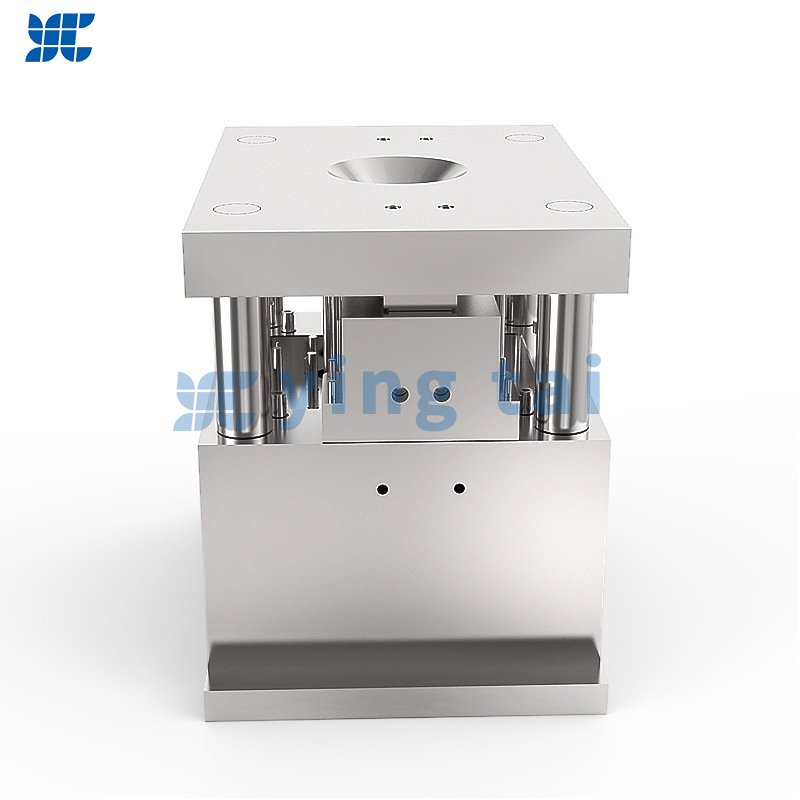

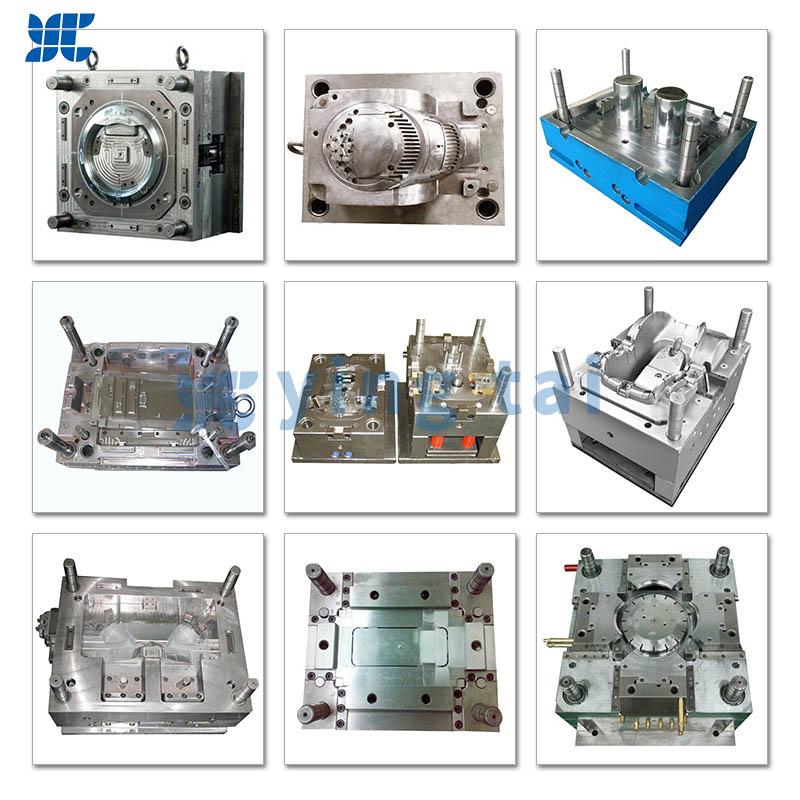

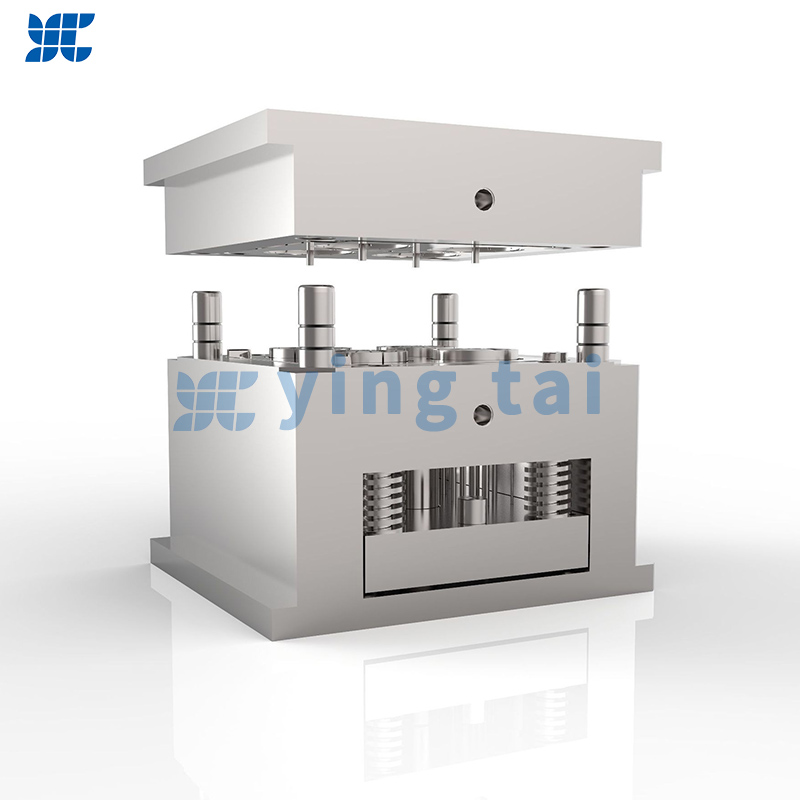

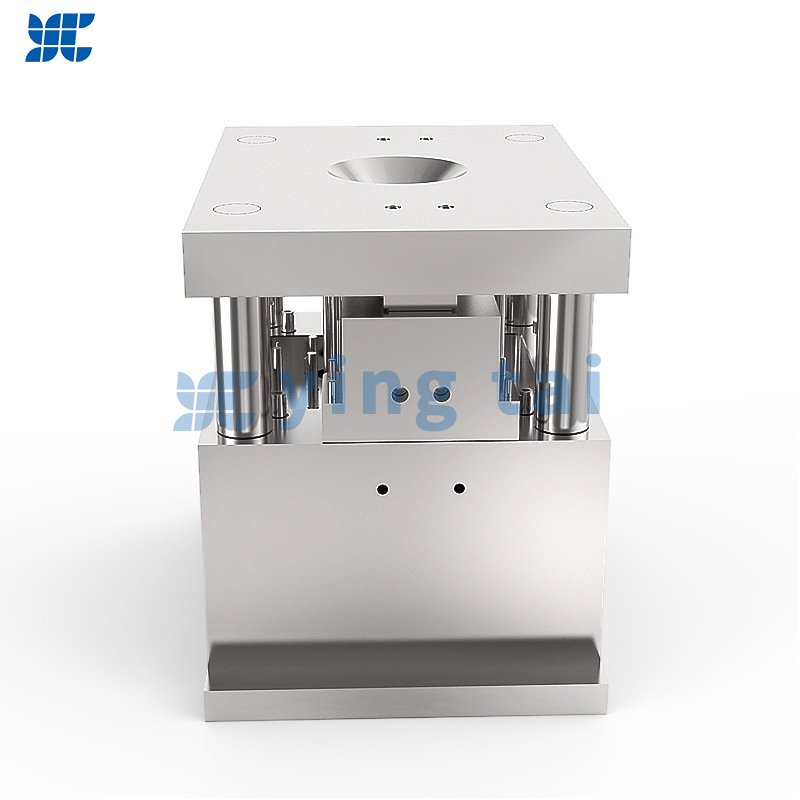

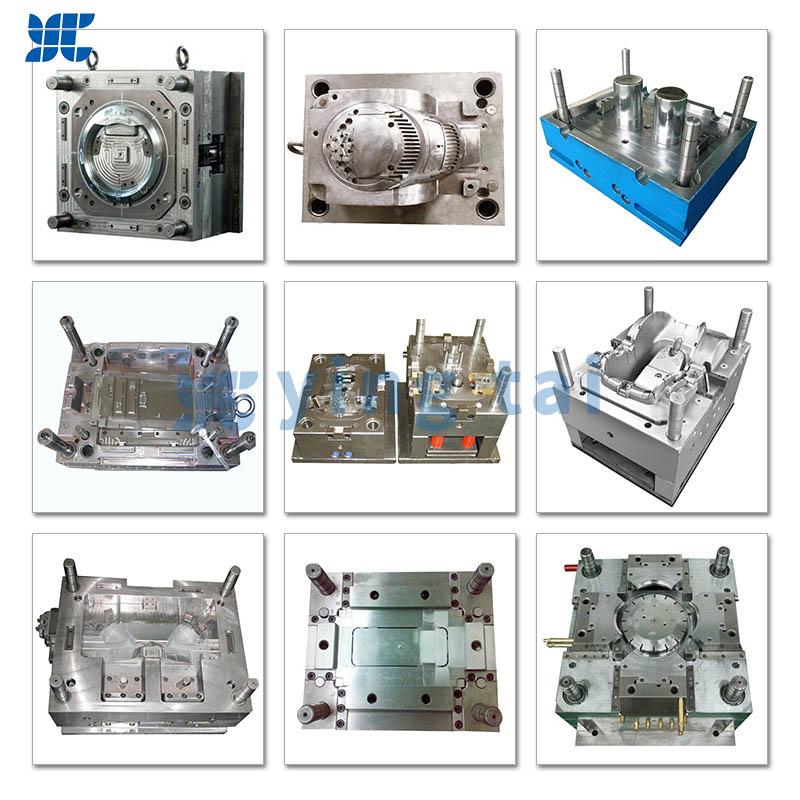

2. Mold preparation: mold design: mold design according to product requirements. Mold cleaning: ensure that the mold is free of dust and oil. Release agent coating: easy to release.

3. Mixing liquid silica gel: mixing liquid silica gel and curing agent in proportion and stirring evenly. Add color paste (if necessary) and continue stirring.

4. Vacuum degassing: put the mixed liquid into a vacuum pump to remove bubbles.

5. Injection molding: injection molding: injecting silica gel into the mold by using a liquid silica gel injection machine. Manual pouring: manual pouring can be used in small batch production.

6. Curing: heating curing: heating the mold to 120 C-180 C to accelerate curing. Room temperature curing: part of silica gel can be cured at room temperature for a long time.

7. demoulding: take out the product carefully after curing to avoid damage.

8. Post-treatment: trimming: removing burrs and redundant parts. Cleaning: clean the surface of the product. Secondary curing: some products need secondary curing to improve performance.

9. Quality inspection: dimensional inspection: to ensure that it meets the design requirements. Performance test: such as heat resistance, chemical resistance, etc.

10. Packaging and storage: Store after packaging to avoid pollution and damage.

Note: accurate proportion: ensure the correct proportion of silica gel and curing agent. Avoid bubbles: The degassing step is very important. Environmental control: temperature and humidity affect the curing effect.

summary

The production of liquid silica gel products in Yingtai factory includes material preparation, mold preparation, mixed silica gel, injection molding, curing, demoulding, post-treatment and quality inspection. Mastering these steps can produce high-quality liquid silica gel products.

Liquid silicone mold coating, liquid silicone mold design, liquid silicone injection mold, liquid silicone mold opening, liquid silicone mold design, liquid silicone mold cold runner, liquid silicone mold, liquid silicone mold with cold runner, liquid silicone and plastic mold molding, liquid silicone mold manufacturer, liquid silicone abrasives customized, liquid two-color silicone mold, Dongguan liquid silicone mold factory, liquid silicone mold manufacturer, liquid silicone mold processing factory, Liquid silicone injection mold manufacturers, liquid silicone mold manufacturers, liquid silicone mold manufacturers, Shenzhen liquid silicone mold factory, Dongguan liquid silicone mold factory, liquid silicone mold manufacturers, liquid silicone mold without flash lsr, liquid injection silicone mold, Dongguan liquid silicone mold manufacturing, liquid silicone mold without flash, Guangdong liquid silicone mold, lsr liquid silicone injection mold processing, liquid silicone two-color mold, liquid silicone mold products