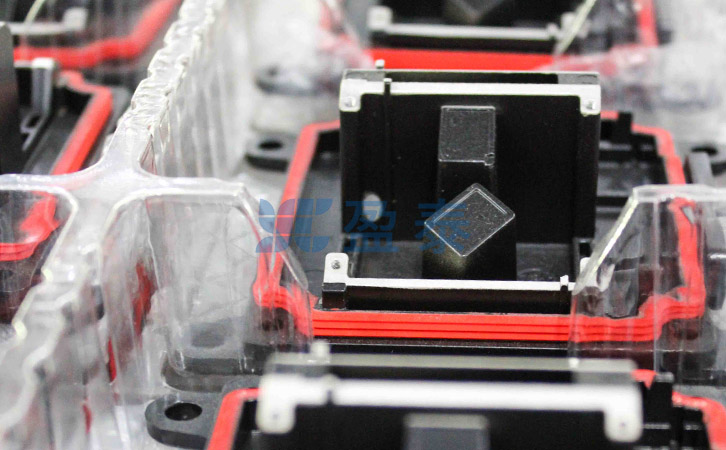

Advantages and Applications of Liquid Silicone Coated Metal Parts

advantage

High sealing performance: Liquid silicone rubber (LSR) has good fluidity and can tightly wrap around metal parts, forming waterproof and dustproof barriers, suitable for harsh environments.

Strong weather resistance: resistant to high and low temperatures (-50 ℃~200 ℃), UV resistance, aging resistance, suitable for outdoor and industrial scenarios.

Soft cushioning: Silicone has excellent elasticity, shock absorption and drop resistance, and protects metal core components (such as electronic components).

Insulation safety: Silicone is non-conductive and can be insulated after being coated with metal, improving electrical safety.

Chemical stability: acid and alkali resistance, corrosion resistance, suitable for special environments such as medical treatment and chemical engineering.

Integrated molding: Seamless integration of metal and silicone through molding process, reducing assembly steps and lowering costs.

purpose

Electronic appliances: waterproof charging interface, sensor housing, smart wearable devices (such as metal contacts for heart rate monitoring on watches).

Automotive industry: car buttons, sealing rings, wire harness connectors, oil and high temperature resistant.

Medical treatment equipment: handle, implanted device coating, high biocompatibility.

Household items: kitchenware handle (heat-resistant), shaver waterproof structure.

Industrial components: valve seals, pipeline connectors, corrosion-resistant and wear-resistant.

Liquid silicone coated metal parts combine the strength of metal with the flexibility of silicone, and are widely used in precision parts that require sealing, insulation, or human-machine interaction