The liquid silicone product manufacturer will tell you the steps required for the liquid silicone molding process

The main products of liquid silicone products in the injection molding manufacturing process are very obvious. The traditional working process focuses on the pressure impact mixing process, which is mixed by a mechanical mixing method that combines two components together.

The main steps of the liquid silicone rubber molding process involved here are:

1. The silicone rubber sealing ring manufacturer introduces that uncured organic silicone is placed in a container and divided into compounds A and B, which are connected to the pumping system. The barrel holds the material for forming the base, and barrel B contains the catalyst. One unit of measurement automatically releases two substances in a constant 1:1 ratio, as well as any pigment additives.

Liquid silicone product manufacturer

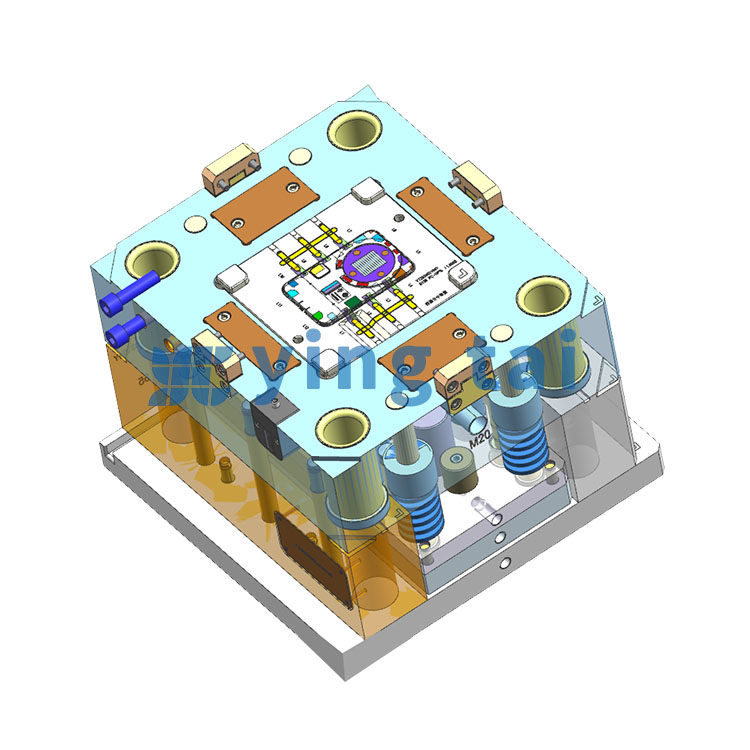

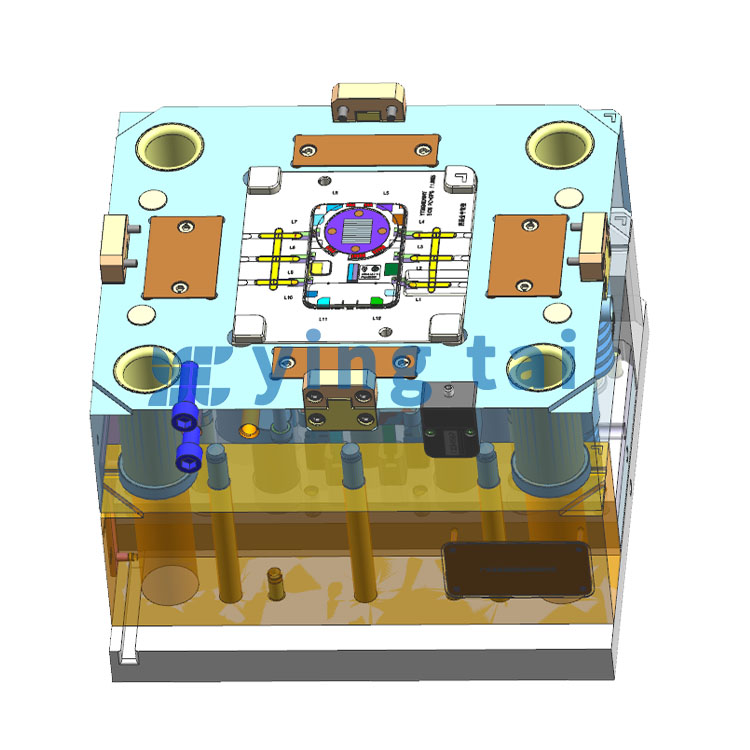

2. Injection molding can be divided into two programs: custom automatic injection molding machines and injection molding settings that provide corresponding lens sizes for each job. Template and piston, adjust and close the mold, have temperature, set pressure according to customer specifications based on injection speed and cycle time.

3. After installation, the machine heats the mold to the appropriate temperature and applies the appropriate clamping force. The mold is closed in conjunction with the injector, pump, and supply of the machine. Inject mechanism and push materials into the mold cavity.

4. A combination of heat and pressure is applied to the liquid silicone rubber curing material until it solidifies. Upon completion of the cycle, the mold opens and some parts flicker, which can be automatically or removed by a worker. Then, the mold is closed and the process is repeated.

5. Introduction to liquid silicone rubber molding process by silicone sealing ring manufacturers: After removing the item from the mold, the post molding process may include flashing, post curing, inspection, and packaging.

The above is a description of the steps involved in the molding process of liquid silicone rubber products. We hope it can be helpful to you.

Liquid silicone wrap plastic, liquid silicone wrap plastic, liquid silicone wrap hardware, liquid silicone wrap metal, liquid silicone wrap aluminum alloy, liquid silicone wrap injection molding, liquid silicone wrap rubber, liquid silicone wrap plastic products, liquid silicone wrap plastic products, liquid silicone wrap hardware products, liquid silicone wrap metal products, liquid silicone wrap aluminum alloy products, liquid silicone wrap injection molding products, liquid silicone wrap rubber products, liquid silicone wrap plastic products, liquid silicone wrap hardware products, liquid silicone wrap metal products, liquid silicone wrap aluminum alloy products, liquid silicone wrap injection molding products, liquid silicone wrap rubber shell for power banks, magnetic suction power bank silicone waterproof shell, wireless power bank silicone rubber waterproof accessories, magnetic suction wireless power bank silicone wrap plastic shell The, Large capacity magnetic power bank injection molded plastic case, ultra-thin magnetic power bank plastic waterproof case, fast charging power bank silicone plastic case, fast charging power bank with wire silicone rubber product case