Factories and workshops that produce liquid silica gel (lsr) products need to meet the following requirements to ensure product quality and production efficiency:

1. Environmental control

Temperature and humidity: The workshop should keep constant temperature and humidity, usually the temperature is controlled at 20-25 C and the humidity is controlled below 50% to avoid affecting the curing process of silica gel.

Cleanliness: The workshop should be kept highly clean to avoid dust and impurities polluting products, especially medical and food-grade products.

2. Equipment requirements

Mixing equipment: high-precision mixing equipment to ensure that liquid silica gel and curing agent are evenly mixed in proportion.

Vacuum degassing equipment: used to remove bubbles in the mixed liquid to ensure product quality.

Injection molding machine: used to inject liquid silica gel into the mold, and the equipment should have precise-accurate-temperature and pressure control.

Heating and curing equipment, such as oven or heating plate, is used to accelerate the curing process of silica gel.

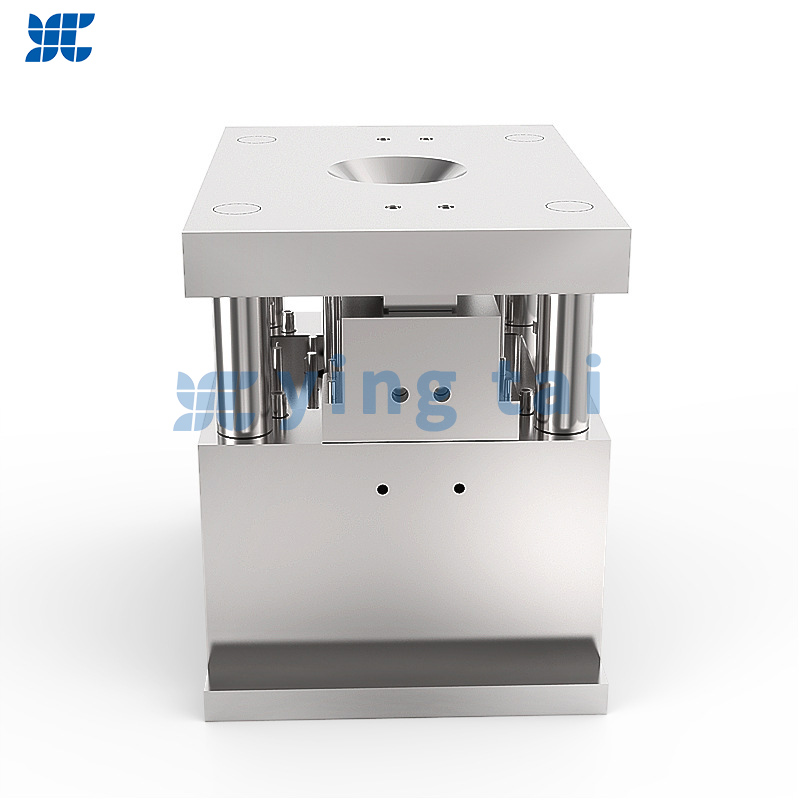

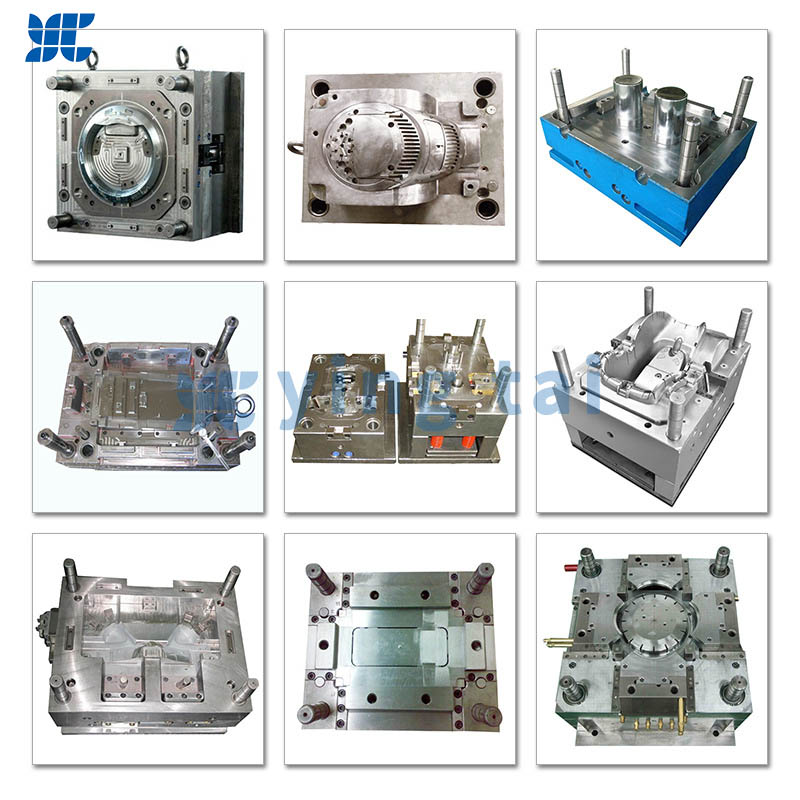

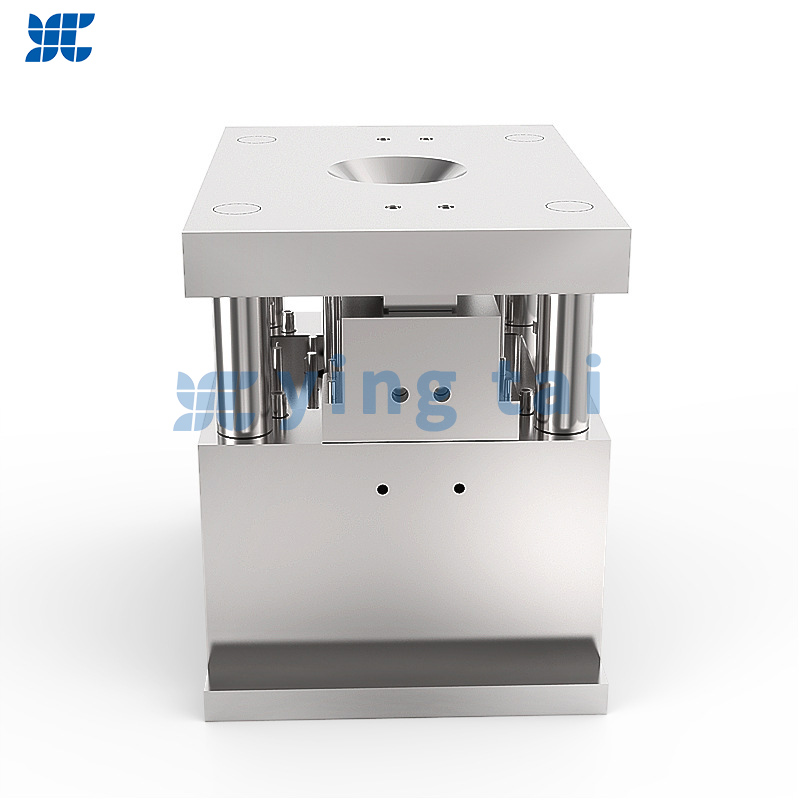

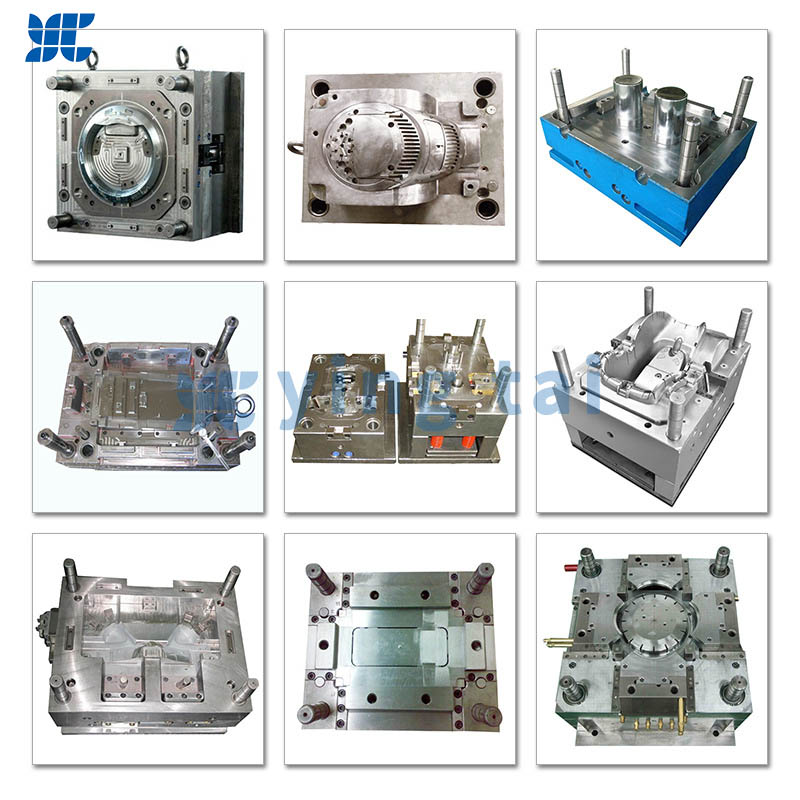

Mold: high-precision mold to ensure the accuracy of product size and shape.

3. Workshop layout

Raw material storage area: used to store raw materials such as liquid silica gel, curing agent and color paste, which should be kept dry and clean.

Mixing and degassing area: special area for mixing and degassing silica gel to avoid cross-contamination.

Injection molding and curing area: equipment layout is reasonable to ensure smooth operation process.

Post-treatment area: used for post-treatment operations such as trimming, cleaning and secondary curing.

Quality inspection area: equipped with necessary inspection equipment for size and performance testing.

Finished product storage area: used to store finished products to avoid pollution and damage.

4. Safety requirements

Ventilation system: good ventilation system to eliminate harmful gases and odors.

Protective equipment: Operators should wear protective gloves, masks and goggles to avoid contact with harmful substances.

Emergency measures: equipped with emergency eye washer and first aid kit to deal with-sudden-hair-situation.

5. Personnel requirements

Training: The operators should be trained in specialty, industry and be familiar with the characteristics and production process of liquid silica gel.

Hygienic requirements: Operators should maintain personal hygiene and wear clean work clothes and shoe covers.

6. Quality control

Process control: strictly monitor each production link to ensure product quality.

Testing equipment: equipped with necessary testing equipment, such as caliper, hardness tester, tensile tester, etc.

Record and traceability: record all parameters in the production process in detail to facilitate quality traceability.

7. Environmental protection requirements

Waste disposal: properly handle the waste and waste water generated in the production process, in line with environmental protection requirements.

Energy saving and emission reduction: adopt energy-saving equipment to reduce energy consumption and emission.

Factories and workshops that produce liquid silica gel products need to strictly control the environment, equipment, layout, safety, personnel, quality and environmental protection to ensure product quality and production efficiency. Through reasonable design and management, high-quality liquid silica gel products can be produced.

Lsr liquid silicone mold, liquid silicone mold factory, liquid silicone mold manufacturer, lsr liquid silicone mold factory, liquid silicone mold processing, cleaner liquid silicone mold, liquid silicone mold manufacturer, liquid silicone mold manufacturer, liquid silicone mold production, liquid silicone mold company, Dongguan liquid silicone mold manufacturer, liquid silicone mold factory, silicone rubber coating, silicone rubber coating customization, Silicone packaging manufacturer, customized silicone packaging, Shenzhen silicone packaging manufacturer, Guangdong silicone packaging manufacturer, Shenzhen silicone packaging supplier, hardware silicone packaging manufacturer, silicone packaging manufacturer, Guangdong silicone packaging manufacturer, sim card packaging adhesive, mobile phone card holder packaging adhesive, connector silicone packaging adhesive, silicone waterproof packaging adhesive, silicone packaging adhesive factory, typec packaging adhesive, earphone socket packaging adhesive, Shenzhen